-

News

News -

- Video

- VR panoramic video

- Case video

Video

Video

The latest, most popular and comprehensive intelligent business display product news information is presented for you.

Release time:2020-08-27

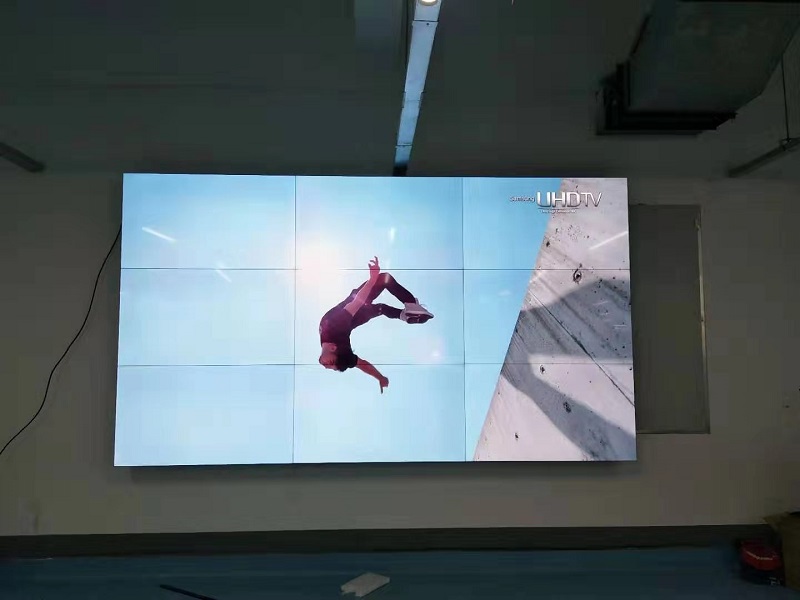

The installation of seamless LCD splicing screen is not like ordinary display equipment, just simply put it on and install it. The installation of seamless LCD splicing screens should not only choose the installation site carefully, but also pay attention to the light around the installation environment, and also need to pay attention to the wiring, and there are also requirements and choices for the frame. Let's talk about how to install a seamless LCD splicing screen.

Choice of installation ground:

The installation ground of the seamless LCD splicing screen should be flat, because the entire system of the seamless LCD splicing screen is relatively large in terms of volume and weight. The selected floor also needs to have a certain ability to bear weight. If the floor is tile, it may not bear its weight. Another point is that the installed ground must be anti-static.

Notes on wiring:

When installing a seamless LCD splicing screen, pay attention to distinguishing its power line and signal line when wiring, and install them in different places to avoid interference. In addition, according to the size and installation position of the screen of the entire project, calculate the length and specifications of the various lines needed, and calculate the needs of the entire project.

Ambient light requirements:

Although the brightness of the seamless LCD splicing screen is very high, it is still limited after all, so the light around the environment where you choose to install cannot be too strong. If it is too strong, you may not see the picture on the screen. The light that may enter near the screen (such as windows) should be blocked if necessary. At the same time, it is best to turn off the light when the device is running to ensure the normal operation of the device. Do not install a light directly in front of the screen, just install a downlight.

Framework requirements:

In order to facilitate the maintenance of the seamless LCD splicing screen in the future, the frame edging must be a detachable edging. A gap of about 25mm is reserved on each side of the inner edge of the outer frame from the outer edge of the splicing wall, and the margin should be appropriately increased according to the number of columns in the large splicing wall. In addition, in order to enter the cabinet for maintenance later, the maintenance channel is in principle not less than 1.2m wide. The detachable side strips should preferably be pressed 3-5mm from the edge of the screen. After the cabinet and the screen are fully installed in place, the detachable side strips are finally fixed.

Ventilation requirements:

In the maintenance passage, air conditioners or air outlets must be installed to ensure that the equipment is well ventilated. The position of the air outlet should be as far away as possible from the LCD splicing wall (about 1m is better), and the wind from the air outlet should not be directly blown to the cabinet to avoid damage to the screen due to uneven heating and cooling.

In the LCD splicing construction site, the installation and debugging should be based on the phenomenon reflected by the fault to determine the cause, and the synchronization interface and transmission cable of the equipment should be checked, and the synchronization frequency range of the signal source and the display terminal should be compared. If the image has ghosting, check whether the transmission cable is too long or too thin. The solution is to change the cable to test or add a signal amplifier and other equipment. If the focus is not ideal, you can adjust the display terminal. Facing the emergence of problems, we must first learn to analyze, so as to better solve the root cause of the problem. Through strong analysis, inspection time can be shortened. These methods are some methods and techniques for debugging after installation. The installer must be proficient and good, and only professional people can do professional things.

2. Professional knowledge of LCD splicing technology

Manufacturers who develop and produce seamless LCD splicing screens know that the production process of industrial-grade LCD screens is much higher than that of ordinary display equipment. Even with the same panel level, the production requirements for seamless LCD splicing screens are more stringent. Although many security monitoring companies have begun to use seamless LCD splicing screens, their understanding of seamless LCD splicing screens is too simple, and their understanding of industrial-grade display equipment is very simple. In fact, the construction and selection of many seamless LCD splicing screen engineering companies do not meet the specifications at all, even if they choose foreign brands. Many large-screen display projects have not fully exploited the advantages of seamless LCD splicing screens, and have not achieved high-definition effects and minimal joints. From a microscopic point of view, more companies only know the installation, but neglect to master the necessary knowledge. Today, seamless LCD splicing screen manufacturers add some professional knowledge for everyone.

1. The comparative advantages of seamless LCD splicing screen and other computer monitors

The seamless LCD splicing screen uses an A-level LCD panel, high reliability to ensure quality display. For large screens, the role of the LCD panel is undoubtedly the most important, which accounts for about 70% of the cost, and the general display chooses A The level panel will increase. At present, LCD panels are divided into A+, A-, B+, and B-. The B+ panel is a good choice for computer monitors, but the seamless LCD splicing screen application environment also determines the higher requirements for LCD panels.

2. Seamless LCD splicing screen ultra-narrow frame design

The seamless LCD splicing screen has no frame, slim design on both sides, and uses less than 1 mm cable, which is significantly better than the BSV LCD splicing technology of general display equipment. It is bound to set off an upsurge of seamless LCD splicing in the monitoring field, which will form a "blowout effect" of market demand.

3. High resolution seamless LCD splicing screen supports point-to-point display

For "other devices", the main focus is on the signal input processing chip. Although the parameters shown can reach 1080P, they are not full HD HDCP displays. The liquid crystal displays are not point-to-point horizontal by 1920, A display panel composed of 1080 pixels vertically.

4. The seamless LCD splicing screen uses high-quality electronic components (IC, capacitors, inductors, etc.)

The quality of seamless LCD splicing screen products has a strict component selection system and a complete production line. The products of each production line go through strict baking machines and tests. Unlike "other machines", the procurement time of panels is very tight when leaving the factory, and the production and assembly are free to leave the factory. Because "other machines" do not have products in stock, the panel assembly, production, processing, and installation for customers only when they are delivered, the time is generally very short. The quality of IC, capacitors, and inductors directly affect the life and safety of the display.

5. The seamless LCD splicing screen has unique DNIEPro color and signal enhancement complementary technology

For liquid crystal displays, the control IC that restores precise color control can make the display effect of the liquid crystal display more colorful. Its control IC can screen out 1 billion best colors from about 68.6 billion colors, which is more accurate in restoring the colors of objects. The general display signal board simply decodes the signal and displays it directly, without IC processing.

6. The seamless LCD splicing screen has a dynamic enhancement signal to ensure the dark and white color and dynamic smear phenomenon

The design and material selection of the IC chip and control circuit of the display are also extremely important. The first-tier manufacturers have their own panel production lines, which can design and develop the control circuit from the most professional perspective. From the materials to the workmanship, the large-screen display can be guaranteed to be long. Stable work with time, while strengthening processing of various input signals to ensure the effectiveness of grayscale.

7. The seamless LCD splicing screen uses advanced power supply DPMS

The DPMS management system maximizes the power supply and signal board to protect the LCD panel while reducing power consumption. In the “l(fā)amp driving circuit” of the display, the high-voltage bar is connected to the lamp tube inside the panel to light it and control its brightness. Therefore, the brightness of the display is mainly related to the number of lamps placed in the panel, the more the number, the higher the brightness. For "other machines", all CCFL tubes in the panel are driven to light up, which makes the display work with high brightness for a long time and long-term heat seriously consumes the life of the panel. Why is the seamless LCD splicing screen called low thermal energy? The mystery of the panel is not on the LCD panel, but the driver motherboard uses the chip to automatically change the CCFL lamp in the panel to light up.

2024-10-10 hbying

2024-09-18 hbying

2024-09-04 hbying

2024-08-20 hbying

2024-08-15 hbying

2024-08-07 hbying